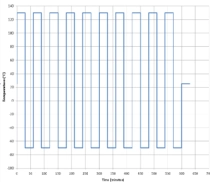

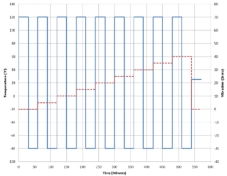

Mit dem MPI 5000A testen wir die Widerstandsfähigkeit Ihres Produkts bei raschen Temperaturänderungen. Unser Spektrum reicht von -70°C bis 220°C. Dank hoher Wechselraten vervollständigen wir bis zu 1.000 Temperaturzyklen in lediglich 48 Stunden.

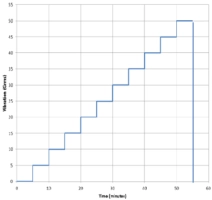

Unser All-Axis-Benchtop Vibration-Table TCB-1.3 testet die Robustheit Ihres Produkts unter mechanischer Belastung. Mit Intensitäten von 1 bis 60 grms und einem Frequenzbereich von 3 Hz bis 10.000 Hz identifizieren wir mechanische Schwachstellen typischerweise innerhalb von 12 Stunden.

Durch die Kombination von mechanischer Belastung und Temperaturschwankungen testen wir Ihr Produkt bis an seine Betriebs- und Belastungsgrenzen. Diese ganzheitlichen Tests liefern verlässliche Daten über die Widerstandsfähigkeit Ihres Produktes. In der Regel werden Grenzwerte und Schwachstellen innerhalb von nur 48 Stunden sichtbar.

Rundum-Service-Paket

Stets Stand der Technik

wir kennen Ihre Branche

Verstehen, was geprüft wird

Transparent terminiert, immer auf dem Laufenden

Vorher wissen, was es nachher kosten wird!

Prüfen, was wirklich notwendig ist

Zur Stelle, wenn es hart auf hart kommt

Die besten Prüfberichte der Welt

“Est duis est sint minim nisi laboris excepteur irure reprehenderit proident dolor ut nulla officia. In occaecat et sit laborum consequat proident adipisicing reprehenderit non. Et id velit ut nostrud.”

“Est duis est sint minim nisi laboris excepteur irure reprehenderit proident dolor ut nulla officia. In occaecat et sit laborum consequat proident adipisicing reprehenderit non. Et id velit ut nostrud.”

“Est duis est sint minim nisi laboris excepteur irure reprehenderit proident dolor ut nulla officia. In occaecat et sit laborum consequat proident adipisicing reprehenderit non. Et id velit ut nostrud.”

“Est duis est sint minim nisi laboris excepteur irure reprehenderit proident dolor ut nulla officia. In occaecat et sit laborum consequat proident adipisicing reprehenderit non. Et id velit ut nostrud.”

Wir sind spezialisiert auf Prüfungen für Steuergeräte, Steckverbinder und elektrisch betriebenes Interieur von Kraftfahrzeugen. Unsere Expertise deckt zudem eine breite Palette von Branchenstandards ab.

Wir verstehen die Dringlichkeit Ihrer Anfragen und bieten flexible Zeitpläne an. Für Notfälle haben wir die „Prüffeuerwehr“: Wir priorisieren Ihren Prüfnotfall, um schnellstmöglich zu reagieren.

Manchmal laufen die Sachen nicht so, wie man sich vorgenommen hat. SOP ist gefährdet.

Produktion steht. Es gibt einen Rückruf oder es besteht eine Gefährdung von Leib & Leben. Es steht also eine Validierung oder Prüftest an und Sie müssen schnellstmöglich tätig werden. Hier hilft enveon’s Prüffeuerwehr.

Unsere Kunden stammen hauptsächlich aus den Bereichen Automotive, Bahn, Industrie und Medizintechnik. Wir verfügen über umfangreiche Erfahrung in diesen Branchen und passen unsere Dienstleistungen Ihren spezifischen Anforderungen an.

enveon testet eine Vielzahl von Produkten, wobei der Schwerpunkt auf Steuergeräten, Steckverbindern und elektrisch betriebenem Interieur von Kraftfahrzeugen liegt. Wir prüfen, ob Ihr Prüfling hinsichtlich Größe, Gewicht und Funktion zu uns passt.

Für Standardprüfungen finden wir in der Regel innerhalb von zwei Wochen einen Starttermin. Bei dringenden Anfragen können wir dank unserer „Prüffeuerwehr“ schneller reagieren.

Die „Prüffeuerwehr“ ist unser Service für Prüfnotfälle. Wir legen alles andere beiseite, um uns mit höchster Priorität Ihrem dringenden Anliegen zu widmen.

Wir behandeln jede Abweichung und jeden Fehler mit höchster Sorgfalt und arbeiten eng mit Ihnen zusammen, um eine schnelle und effektive Lösung zu finden.

Transparente und regelmäßige Kommunikation ist uns wichtig. Sie werden kontinuierlich über den Status Ihres Projekts informiert.

Unser Kundenservice bedeutet, dass wir Ihnen jederzeit bei Fragen und Problemen zur Seite stehen. Wir legen einen großen Wert darauf, dass Sie sich bei uns gut aufgehoben fühlen.

Wir sind sehr kundenorientiert und passen unsere Prozesse flexibel an Ihre sich ändernden Anforderungen an.

Falls Ihr Prüfling nicht wie vereinbart eintrifft, besprechen wir gemeinsam die nächsten Schritte. Unser Ziel ist es, eine für beide Seiten zufriedenstellende Lösung zu finden.

Um Ihnen ein optimales Erlebnis zu bieten, verwenden wir Technologien wie Cookies, um Geräteinformationen zu speichern und/oder darauf zuzugreifen. Wenn Sie diesen Technologien zustimmen, können wir Daten wie das Surfverhalten oder eindeutige IDs auf dieser Website verarbeiten. Wenn Sie Ihre Zustimmung nicht erteilen oder zurückziehen, können bestimmte Merkmale und Funktionen beeinträchtigt werden.