Using HALT, weak points in the design can be identified in early development phases. With HALT, products are exposed to extreme conditions that go far beyond expected operating conditions. The goal is to improve the design by finding out under what conditions the product will fail.

HASS is used in the production phase to identify and reject defective products before they are delivered to customers. Based on the findings of HALT, we support the determination of the stress factors for HASS and thus secure ongoing production.

Our HALT/HASS procedures enable faster defect identification due to extreme mechanical and thermal stress compared to conventional service life tests. This means you can detect errors in hours instead of weeks, saving development time and costs.

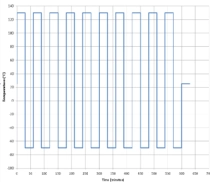

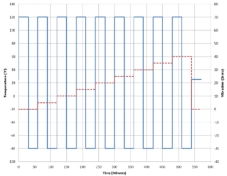

With the MPI 5000A we test the resistance of your product to rapid temperature changes. Our scope ranges from -70°C to 220°C. Thanks to high change rates, we complete up to 1.000 temperature cycles in just 48 hours.

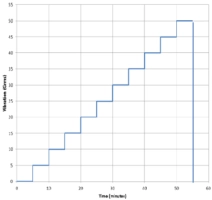

Our all-axis benchtop vibration table TCB-1.3 tests the robustness of your product under mechanical stress. With intensities from 1 to 60 grms and a frequency range from 3 Hz to 10.000 Hz, we typically identify mechanical weak points within 12 hours.

By combining mechanical stress and temperature fluctuations, we test your product to its operating and load limits. These holistic tests provide reliable data about the resilience of your product. Typically, limits and vulnerabilities become visible within just 48 hours.

All-round service package

Always state of the art

we know your industry

Understand what is being tested

Transparently scheduled, always up to date

Know beforehand what it will cost afterwards!

Check what is really necessary

There when the going gets tough

The best test reports in the world

“Est duis est sint minim nisi laboris excepteur irure reprehenderit proident dolor ut nulla officia. In occaecat et sit laborum consequat proident adipisicing reprehenderit non. Et id velit ut nostrud.”

“Est duis est sint minim nisi laboris excepteur irure reprehenderit proident dolor ut nulla officia. In occaecat et sit laborum consequat proident adipisicing reprehenderit non. Et id velit ut nostrud.”

“Est duis est sint minim nisi laboris excepteur irure reprehenderit proident dolor ut nulla officia. In occaecat et sit laborum consequat proident adipisicing reprehenderit non. Et id velit ut nostrud.”

“Est duis est sint minim nisi laboris excepteur irure reprehenderit proident dolor ut nulla officia. In occaecat et sit laborum consequat proident adipisicing reprehenderit non. Et id velit ut nostrud.”

At enveon we usually find a start date for standard exams within two weeks. Our flexibility allows us to respond quickly to your needs.

We specialize in testing control units, connectors and electrically operated interiors of motor vehicles. Our expertise also covers a wide range of industry standards.

We understand the urgency of your requests and offer flexible schedules. We have the “testing fire brigade” for emergencies: We prioritize your testing emergency in order to react as quickly as possible.

Sometimes things don’t go the way you planned. SOP is at risk.

Production stands. There is a recall or there is a risk to life and limb. So a validation or test is pending and you need to take action as quickly as possible. This is where enveon’s testing fire brigade helps.

Our customers mainly come from the automotive, commercial vehicles, railway, industrial and medical technology sectors. We have extensive experience in these industries and tailor our services to your specific requirements.

enveon tests a variety of products, with a focus on control units, connectors and electrically powered automotive interiors. We check whether your test specimen suits us in terms of size, weight and function.

We usually find a start date for standard exams within two weeks. If you have urgent inquiries, we can respond more quickly thanks to our “testing fire brigade”.

The “testing fire brigade” is our service for testing emergencies. We put everything else aside to devote ourselves to your urgent concern as a top priority.

We treat every deviation and error with the utmost care and work closely with you to find a quick and effective solution.

Transparent and regular communication is important to us. You will be continuously informed about the status of your project.

To us, customer service means that we are always available to help you with any questions or problems. We attach great importance to ensuring that you feel in good hands with us.

We are very customer-oriented and adapt our processes flexibly to your changing requirements.

If your specimen does not arrive as agreed, we will discuss the next steps together. Our goal is to find a solution that is satisfactory for both parties.