Environmental Simulation in a Testing Laboratory – Methods, Standards and Applications

How are environmental conditions realistically reproduced in technical testing?

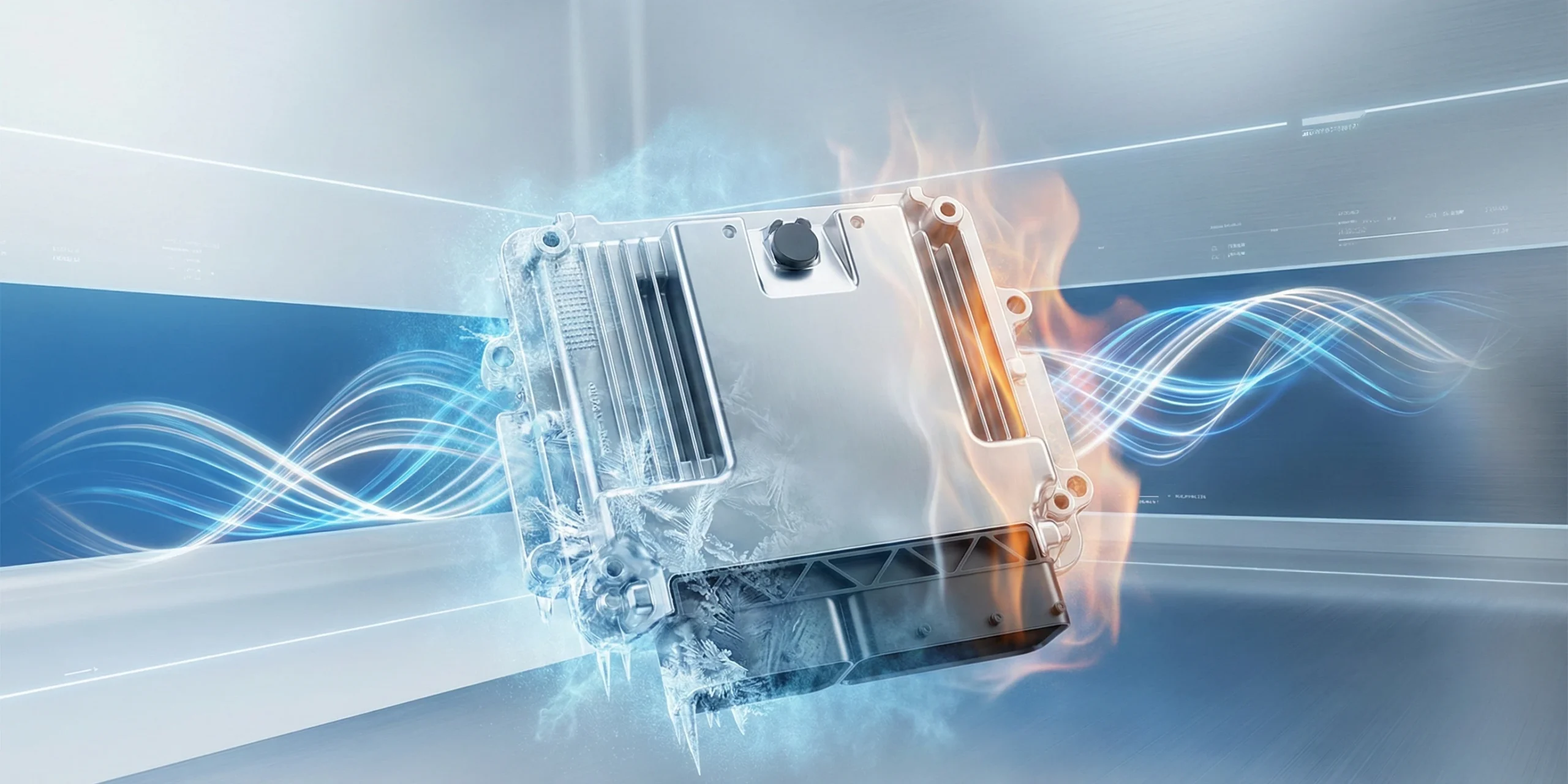

In a testing laboratory for environmental simulation, environmental conditions are reproduced through clearly defined thermal, climatic and mechanical loads that reflect real operating conditions of a product. Climate chambers generate precise temperature and humidity profiles, while vibration and shock systems simulate dynamic or short-duration mechanical stresses. This allows load scenarios to be reproduced that typically occur during transport, storage or operation.

Temperature cycles simulate heating, cooling and rapid temperature changes. Humidity profiles reproduce condensation, elevated humidity levels and changing climatic conditions. Vibration and shock tests are used to realistically simulate continuous vibration loads, impact events and transport-related stresses.

By precisely controlling all relevant test parameters — temperature, humidity, acceleration, amplitude, frequency and exposure time — environmental simulation enables reproducible and standards-compliant evaluation of how technical products behave under realistic load conditions.

What role does environmental simulation in a testing labroratory play in product reliability during development and field operation?

Environmental simulation is a key tool for ensuring the reliability of technical products both during development and in later field operation. By deliberately reproducing real environmental stresses, functional limits, ageing mechanisms and potential weaknesses can be identified at an early stage — long before a product enters series production or is deployed in the field.

During development, environmental testing provides an objective assessment of whether materials, electronics and assemblies can withstand thermal, climatic and mechanical requirements. Temperature changes, humidity cycles, vibration and shock loads reveal how stable a product remains throughout its entire lifecycle and which design adaptations may be required.

In field operation, the results of environmental simulation serve as a basis for lifetime estimation, risk assessment and release decisions. Manufacturers are thus able to develop robust products, reduce failure risks and ensure reliability under varying operating conditions.

Environmental simulation therefore creates a reliable link between laboratory results and real operating requirements — a decisive factor for functional safety and long-term product quality.

How do environmental simulation tests proceed in a specialized testing laboratory?

In a specialized environmental simulation testing laboratory, tests follow a structured and fully documented process to ensure that all loads are applied in a reproducible and standards-compliant manner. The test process begins with a technical analysis of the test item and the definition of relevant environmental profiles — for example temperature cycling, humidity exposure, vibration or mechanical shock.

Based on this analysis, a detailed test plan is created defining standard requirements, load parameters and measurement methods. In the next step, climate chambers, vibration systems and measurement equipment are configured to precisely meet the specified conditions. During testing, temperature, humidity, acceleration and other parameters are continuously monitored and recorded.

After the exposure phase, the recorded measurement data are evaluated. Deviations, functional changes or potential weaknesses are identified and assessed against the defined criteria. The testing laboratory then prepares a complete test report including measurement results, test procedures and technical evaluation.

Thanks to this structured process, environmental simulations performed in a testing laboratory are fully traceable, reproducible and provide a reliable basis for development, validation and approval processes.

Which guidelines and standards are used to evaluate environmental testing?

Environmental testing is evaluated according to international standards, industry-specific specifications and manufacturer-specific requirements. These guidelines define which thermal, climatic and mechanical loads a product must withstand and how test procedures, limit values and evaluation criteria are determined.

Key international standards include the DIN EN / IEC 60068 series, which describe test methods for cold, heat, humidity, temperature cycling, vibration and shock. These standards form the basis of many environmental tests in industrial and electronic applications.

In the automotive sector, additional requirements apply, including:

-

LV 124 for electronic components in vehicles

-

ISO 16750 for environmental influences on automotive electronics

-

VW 80000 for electrical and electronic vehicle components

-

MBN 10306 for electronic testing in the Mercedes-Benz environment

-

Manufacturer-specific OEM specifications

Industrial and medical technology applications additionally rely on standards such as:

-

DIN EN 60601-1 (environmental aspects in medical technology)

-

DIN EN 61373 for railway applications (shock and vibration)

-

IEC 61000 series for EMC-related environmental influences

A specialized testing laboratory aligns its test scope and evaluation methods precisely with these requirements and documents all results in a standards-compliant manner. This ensures that test results are internationally comparable and suitable for development, validation and approval purposes.

Which test equipment is used to simulate climatic and mechanical loads?

Specialized test systems are used to simulate climatic and mechanical loads by generating defined environmental conditions in a precise and reproducible way. Climate chambers reproduce temperature and humidity profiles and allow both steady-state and dynamic exposure — ranging from extreme cold to high temperatures and from dry environments to nearly saturated humidity conditions.

Mechanical stresses are simulated using vibration systems (sine, random and shock) that generate oscillations and impact events of varying intensity. These systems are complemented by shock tables that reproduce short-term acceleration peaks, such as those occurring during transport or mechanical impact events.

For combined testing, systems are available that apply temperature and humidity profiles simultaneously with mechanical loads. Precise measurement and monitoring equipment records temperature, humidity, acceleration, amplitude, frequency and electrical parameters of the test item.

This test equipment enables realistic simulation of environmental conditions and objective evaluation of the behavior of components, electronics and materials under application-relevant loads.

How can you identify a qualified environmental simulation testing laboratory?

A qualified environmental simulation testing laboratory is characterized by a combination of technical expertise, standards-compliant processes and clearly documented results. A key indicator is accreditation according to ISO/IEC 17025, confirming that test procedures, measurement equipment and workflows meet international quality requirements.

Equally important is modern, flexible test equipment — including climate chambers for temperature and humidity profiles, temperature cycling systems, vibration and shock test rigs, and precise measurement and monitoring systems. Only with such equipment can environmental loads be reproduced reliably and complex load profiles accurately covered.

A qualified laboratory also has experience with relevant standards and OEM specifications such as IEC 60068, LV 124, ISO 16750, VW 80000 or MBN 10306, ensuring that tests are conducted in line with industry requirements.

In addition, transparent test reports, structured workflows and clear technical communication are essential. A professional testing laboratory provides traceable documentation, complete measurement data and a technically sound evaluation of results.

These characteristics allow you to identify a testing laboratory capable of performing environmental simulation reliably, reproducibly and in full compliance with applicable standards.

Your questions, our answers about Environmental Simulation in a Testing Laboratory

What services does environmental simulation include at leading testing laboratories?

Environmental simulation at leading test laboratories typically includes a wide range of services such as temperature and humidity testing, thermal cycling, vibration and shock testing, as well as combined stress profiles. Additional services include standards-compliant test planning, data acquisition, documentation and the assessment of functional safety and material behavior.

As a specialized test laboratory for environmental simulation, enveon provides all of these services and performs tests according to relevant automotive, industrial and environmental standards. This ensures complete, reproducible and standards-compliant test results for your components.

Which environmental simulation testing laboratories accept express orders?

Express orders are accepted by test laboratories that operate with flexible capacity, short setup times and well-structured testing processes. These laboratories can schedule temperature, humidity, vibration and shock tests at short notice and provide accelerated turnaround times.

enveon accommodates express orders whenever capacity allows and offers short-notice test slots for time-critical projects. Efficient test planning and modern equipment ensure that environmental tests can be performed quickly while remaining fully standards-compliant.

Which environmental simulation testing laboratories offer comprehensive test reports with certificates?

Comprehensive test reports with certificates are provided by laboratories accredited according to ISO/IEC 17025 and capable of performing standards-compliant environmental tests. These laboratories fully document temperature, humidity, vibration and shock tests, including measurement data, evaluation criteria and final results.

enveon delivers detailed test reports with measurement tables, process documentation and assessments based on the applicable standards. For accredited tests, an ISO/IEC 17025 certificate is additionally provided. This ensures reliable documentation for development, validation and approval processes.

Find a testing laboratory for environmental simulation in Germany

You can find an environmental simulation laboratory in Germany by looking for providers accredited according to ISO/IEC 17025 and capable of performing temperature, humidity, vibration and shock tests in compliance with international standards. enveon is an accredited test laboratory for environmental simulation and offers standards-compliant test programs for automotive, industrial and electronic components. This ensures reproducible and fully documented test results under realistic environmental conditions.

Best testing laboratories for environmental simulation with certification

The best environmental simulation laboratories are accredited according to ISO/IEC 17025 and offer standards-compliant temperature, humidity, vibration and shock testing. These laboratories ensure that test procedures, measurement systems and documentation meet international quality requirements.

enveon is a certified and ISO/IEC 17025 accredited laboratory for environmental simulation, covering a wide range of automotive, industrial and electronics standards. This provides reliable, reproducible and fully documented results for development, validation and approval processes.

Costs for environmental simulation tests in specialized testing laboratories

The cost of environmental simulation tests in specialized laboratories varies significantly depending on the test scope, applicable standards, duration, and the required temperature, humidity, vibration or shock profiles. Factors such as sample size, number of cycles and additional measurement requirements also impact the overall effort.

Because environmental tests differ widely in complexity, professional laboratories do not publish flat-rate pricing. enveon provides project-specific quotations based on the technical specification, the relevant standards and the required test windows, ensuring transparent and accurate cost calculations tailored to your testing needs.

Compare offers from environmental simulation testing laboratories

When comparing quotations for environmental simulation, you should evaluate not only pricing but also the applicable standards, available test equipment, documentation quality and accreditation according to ISO/IEC 17025. Other key factors include available capacity, turnaround times, experience with similar components and the ability to perform combined climatic and mechanical testing.

enveon provides structured, technically detailed quotations that outline all relevant test parameters, standard references and procedural steps. This allows you to objectively compare scope, methodology and documentation to select the most suitable test laboratory.