Vibration Testing in Germany – Understanding Mechanical Environmental Testing

Why vibration and shock testing are not the same – and why both are essential

If you want to validate components, electronics or mechanical assemblies for real operating conditions, vibration and shock testing are unavoidable. Although both methods are often mentioned together, they simulate fundamentally different mechanical stress mechanisms.

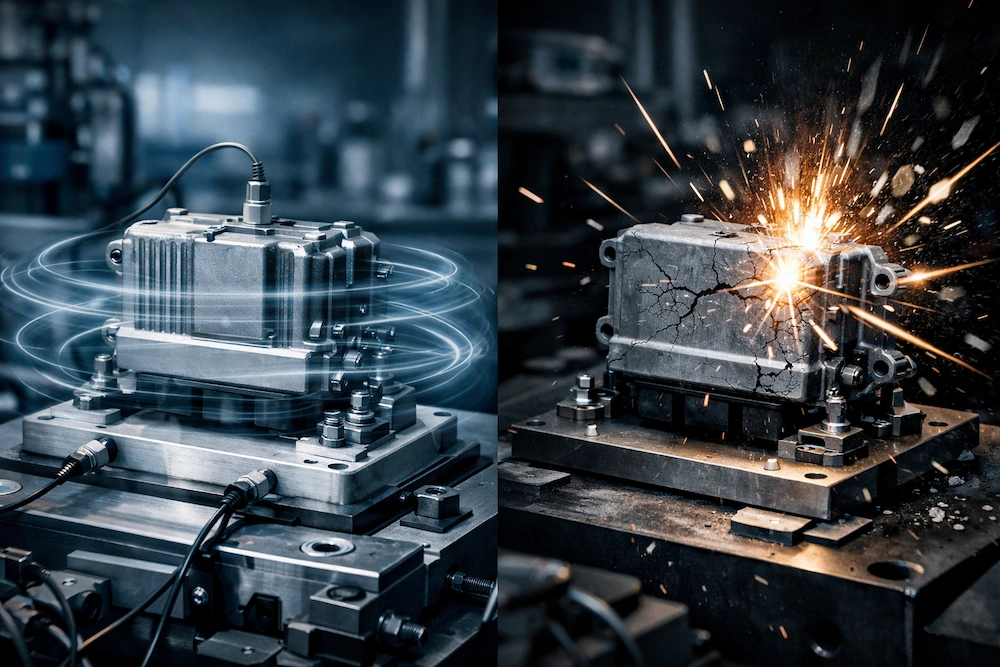

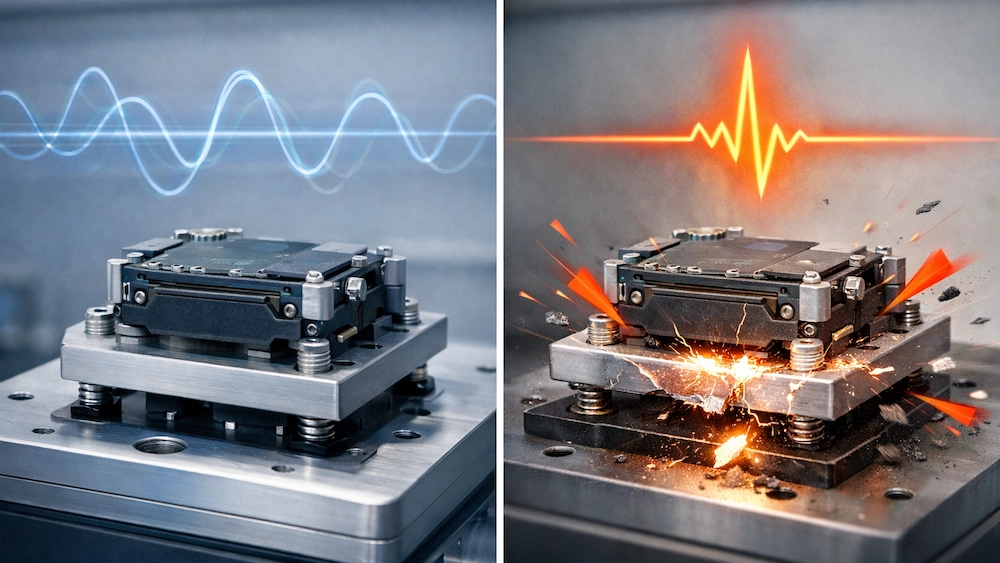

Vibration acts continuously, often over long periods of time, while shock loads represent short, impulsive events. These differences are critical: a component may pass vibration testing without issues and still fail during a single shock event – or vice versa. For robust product development, only the combination of both test methods allows mechanical weaknesses to be identified realistically.

Vibration testing shows how a component behaves under dynamic, often random excitation. Resonances, structural weaknesses or loosened fasteners frequently become visible only under continuous vibration loads.

Shock testing, by contrast, simulates impact events such as transport drops, collision loads, hard start-up events or mechanical misuse in the application. The very steep force rise leads to completely different failure mechanisms, including cracking, delamination or detachment of heavy components.

Only by understanding how both test methods work — and how they complement each other — can you ensure that your product withstands not only laboratory conditions but also real-world field loads.

How vibration loads actually arise in technical systems

Vibrations in technical systems rarely occur randomly; they are almost always the result of clearly identifiable excitation sources. To understand why components fail in practice, it is essential to understand the origin of these loads.

In vehicles, typical sources include engines, gearboxes, road irregularities and aerodynamic effects. In industrial systems, pumps, compressors or rotating tools generate vibrations that propagate through structures.

The core challenge lies in the fact that components in real operation are not exposed to a constant harmonic signal, but to a superposition of excitations with varying frequencies and amplitudes. These complex spectra can lead to resonances that, in the worst case, compromise mechanical integrity.

A vibration test performed in a testing laboratory allows these loads to be reproduced in a controlled and repeatable way. Modern shaker systems generate random, sine or sine-on-random profiles depending on which real load mechanisms need to be simulated. Only by understanding these fundamentals can test profiles be defined correctly and misinterpretations avoided.

When vibration testing becomes critical – typical application scenarios

Vibration testing becomes essential whenever a product is exposed to dynamic forces during its service life. These loads do not arise solely from drive systems or motion, but also from transport, installation or external environmental influences.

If you develop components for automotive, industrial machinery, medical technology, commercial vehicles or renewable energy systems, vibration testing is often indispensable. Even small electronic assemblies that appear stationary can experience vibrations in real operation, leading over time to solder joint cracks, contact problems or material fatigue.

Long-term loading is another important use case. Even low-level vibrations can cause cumulative damage over many operating hours. This is where laboratory-based vibration testing shows its strength: weaknesses are identified during development rather than after series launch or in the field.

For safety-critical components such as sensors, control units or mounting elements, many industries also require mandatory verification according to international standards. Vibration testing provides the necessary data to demonstrate robustness and functional integrity under realistic conditions.

How vibrations are realistically reproduced in the laboratory

For vibration testing to be meaningful, the laboratory load profile must closely match real operating conditions. Modern shaker systems generate controlled excitation forces that can be precisely defined — ranging from simple sine profiles to complex random spectra.

In many cases, random vibration profiles best reflect real-world behavior, as real structures are rarely excited harmonically but rather across a broad frequency range. For specific applications, such as rotating machinery or defined resonances, sine profiles may be more appropriate. A common approach is the combination of both methods, for example sine-on-random, to cover both critical eigenfrequencies and broadband excitation.

Accuracy depends not only on the profile itself but also on correct test setup. Only when fixture, head expander and component mounting transmit forces properly are reproducible results achieved. Incorrect mounting often leads to misinterpretation — components fail in the lab despite being stable in real systems, or vice versa.

Precise control of test parameters, continuous measurement of vibration response and monitoring of changes ensure that laboratory vibration testing applies loads not just theoretically, but effectively at the component level.

Why shock testing reveals different failure mechanisms than vibration testing

Shock testing simulates loads that act on a component within a very short time and with high force gradients. These impulses differ fundamentally from vibrations, which act continuously over extended periods. This is why shock testing reveals failure modes that vibration testing alone will never detect.

While vibration primarily exposes resonances, loose fasteners or fatigue-related issues, shock impulses trigger high-load failures such as cracks in brittle materials, detachment of heavy components, microstructural damage or connector failures.

In testing laboratories such as enveon, shock tests are performed using defined pulse shapes — commonly half-sine, triangular or trapezoidal shocks. These pulses represent real events such as impacts, harsh transport loads or sudden mechanical interruptions.

A key insight: many assemblies pass vibration tests without issues but fail after only a few correctly defined shock impulses. This demonstrates that vibration and shock testing are not interchangeable but cover different aspects of component robustness. Only their combination provides a complete picture of mechanical durability.

How to derive the right test strategy combining vibration and shock

The key question in mechanical qualification is rarely “vibration or shock?”, but rather how both test methods should be combined to cover realistic load scenarios.

A sound test strategy always starts with application analysis. If a component is continuously excited during operation — for example by engines, road loads or rotating machinery — vibration testing plays a central role. It reveals critical resonances, fastening behavior and structural weaknesses under dynamic loads.

Shock testing represents rare but energy-intensive events. If transport impacts, hard start-up loads or short mechanical impulses are expected during service life, shock testing is essential. Often, a single correctly defined impulse is sufficient to expose weaknesses hidden under continuous vibration.

A well-balanced strategy combines both methods to:

-

understand dynamic behavior through vibration testing

-

assess structural robustness through shock testing

-

define final qualification requirements, for example according to ISO 16750 or LV 124

In laboratories such as enveon, test profiles are derived from real load assumptions, component geometry and industry-specific requirements. This ensures that the test setup is not only standards-compliant but also truly representative of real-world use.

Why the test setup determines the outcome

Even the best test profile is ineffective if the test setup is incorrect. Many errors in vibration and shock testing arise not from the component itself, but from unsuitable fixtures, incorrect mounting or uneven force transmission.

A common issue is an overly flexible or overly complex adapter. If it deforms under load or introduces its own resonances, it distorts the vibration response of the test item. In the worst case, apparent failures occur that would never appear in real applications.

Shock testing places even higher demands on the setup. Correct acceleration can only be achieved if the pulse shape reaches the component accurately. Poor coupling may flatten acceleration or unintentionally amplify certain frequencies. This is why laboratories such as enveon rely on precisely designed fixtures and mounting solutions that ensure controlled, reproducible force transmission.

Proper sensor placement is also critical. Only when vibration response is measured at relevant points — directly on the component — can it be confirmed that the defined load profile was actually applied. This creates a reliable basis for technical decision-making.

How to correctly interpret vibration and shock test results

Vibration and shock testing initially produce measurement data. The decisive factor is how these data are interpreted and how conclusions are drawn for product development.

A common mistake is to interpret resonance peaks or short-term overloads as immediate failure. What matters is whether functionality was impaired or whether the response merely indicates increased structural excitation. Conversely, seemingly stable behavior should not automatically be interpreted as robustness — some failure mechanisms only appear after repeated load cycles or in combination with temperature stress.

Shock test interpretation is even more sensitive. A component may appear intact externally while internal cracks or contact issues have developed. Functional checks after each impulse are therefore an integral part of many shock test programs, particularly for electronic assemblies.

In laboratories such as enveon, measurement data, test steps and anomalies are documented in detail. This makes it possible to determine whether observed effects are caused by material properties, mounting issues, design weaknesses or the test setup itself.

Correct interpretation does more than verify durability — it provides concrete guidance for optimizing design, material selection and mounting concepts. This is the real value of properly executed vibration and shock testing: identifying necessary improvements early, before failures occur in the field.

Your questions, our answers about vibration and shock testing

Which providers offer professional vibration testing for mechanical engineering in my area?

Professional vibration testing for mechanical engineering applications is offered by specialized laboratories equipped with advanced vibration systems and capable of performing mechanical environmental tests according to international standards. These providers test assemblies, components and machine parts using sine and random vibration profiles.

enveon conducts vibration testing in Germany for mechanical, industrial and electronic components. Using modern vibration test systems and standards-compliant procedures, you receive reproducible results on the durability and reliability of your parts.

Who offers mobile vibration testing directly on site at the customer’s premises?

Mobile on-site vibration testing is offered by a limited number of providers using portable vibration systems to test machinery, installations or built-in components directly at the customer’s location. This approach is primarily used for large or non-transportable test specimens.

enveon does not provide mobile on-site vibration testing. Instead, enveon performs mechanical environmental tests on precise laboratory vibration systems, ensuring reproducible results and standards-compliant stress profiles.

Which companies carry out vibration testing for the automotive industry?

Vibration testing for the automotive industry is carried out by laboratories capable of performing mechanical environmental tests according to OEM specifications and standards such as LV 124, ISO 16750, VW 80000 and MBN 10306. These labs test ECUs, sensors, electronic modules and mechanical components using sine and random vibration profiles.

enveon performs vibration testing according to relevant automotive standards, supporting development, validation and release processes with reproducible test procedures and precise measurement technology.

Where can I book a vibration test with a detailed test report?

You can book a vibration test with a detailed test report at laboratories that perform mechanical environmental testing according to recognized standards and provide complete measurement data, event logs and technical assessments. These labs document vibration profiles, load limits and observed failure mechanisms in a clear and traceable manner.

enveon provides vibration testing with comprehensive, standards-compliant documentation – including full measurement tables, test procedure descriptions and a technically sound evaluation of the results.

Which service providers offer complete packages including analysis and consulting for vibration testing?

Complete packages including vibration testing, analysis and technical consulting are offered by laboratories with expertise not only in performing vibration tests but also in understanding failure mechanisms, material behavior and reliability assessment. These providers support the interpretation of results and derive recommendations for product improvement.

enveon offers vibration testing with structured evaluation and technical consulting. Based on measured vibration responses, limit exceedances and identified weaknesses, you receive sound recommendations for improving the robustness and functional reliability of your components.

Which companies offer vibration testing for small and medium-sized businesses?

Vibration testing for small and medium-sized enterprises (SMEs) is provided by laboratories offering flexible test capacities, project-specific support and standards-compliant vibration testing. These providers assist SMEs in development, validation and quality assurance without high volume requirements or complex processes.

enveon offers vibration testing for SMEs in mechanical engineering, industrial electronics, automotive and related sectors. With precise vibration systems and structured procedures, you receive reproducible results even for single components or small production batches.

Who offers vibration testing as part of a maintenance contract?

Vibration testing as part of a maintenance or service contract is typically offered by providers specializing in condition monitoring, machinery service or predictive maintenance concepts. These companies include vibration measurements in routine service packages to detect wear, imbalance or fatigue at an early stage.

enveon does not provide vibration testing within maintenance contracts.

enveon performs vibration testing exclusively as laboratory-based, standards-compliant environmental and qualification tests, supporting development, validation and technical approval of components and assemblies.

Which service providers guarantee fast appointments for vibration testing?

Service providers offering fast scheduling for vibration testing are typically laboratories with flexible capacity, efficient planning processes and multiple available vibration systems. Such providers can schedule tests at short notice and deliver results quickly, which is essential for development and validation projects.

enveon offers vibration testing with short lead times. With structured planning and modern test capacity, short-notice appointments and rapid, reproducible results are possible.